How we manufacture products and design systems has transformed significantly as a result of the digitisation of all industries. This transformation and transition have been so compelling that it’s being referred to as Industry 4.0 – the fourth industrial revolution (or 4IR). Industry 4.0 will see many tasks that were once performed by us, now being automated.

This article forms part of a series of articles on Industry 4.0 IoT. In this article we will briefly look at the following:

- What is Industry 4.0

- Industry 4.0 and IoT are not the same

- The 5 layers of Industry 4.0 IoT

- What are the benefits of Industry 4.0

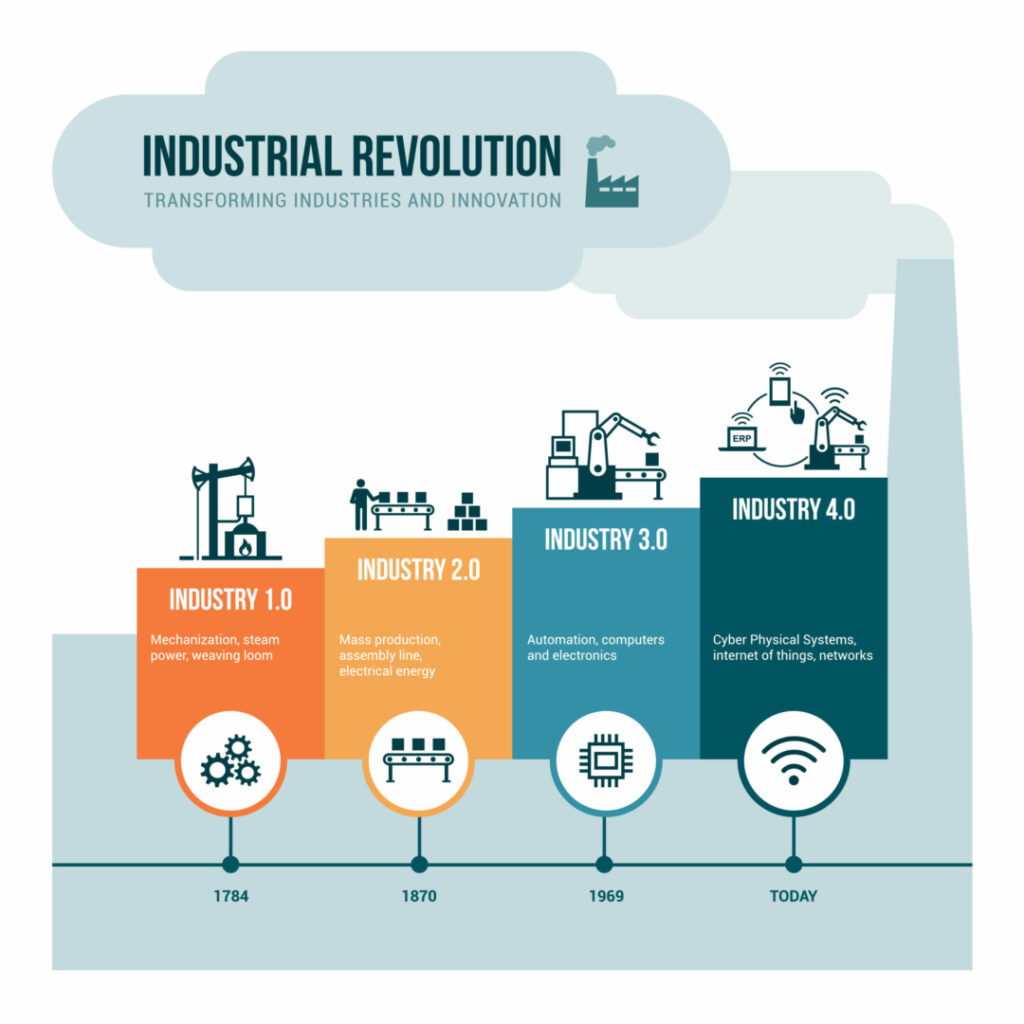

Throughout history, people have always depended on technology. From the first industrial revolution in 1765 (mechanisation and the invention of the steam engine) to the emergence of new sources of energy (electricity, gas, and oil) in the second in 1870 to the third in 1969 which saw the rise of electronics, telecommunications and of course computers. The fourth industrial revolution (or Industry 4.0) is taking what was started in the third and, by adopting computers and automation, is enhancing it with smart and autonomous systems driven by data and machine learning.

1. What is Industry 4.0

Industry 4.0 refers to the fourth industrial revolution and shows a visible trend towards automation and data exchange in technology and the improvement of systems and processes within the manufacturing industry. This automation creates a manufacturing system whereby machines in factories are enhanced with wireless connectivity and sensors to monitor and visualise the entire production process and make autonomous decisions. Industry 4.0 is based on the following principles: Interoperability, decentralisation, real-time analytics, virtualisation service orientation and modularity and scalability.

2. Industry 4.0 and IoT are not the same

Albeit a vital component of Industry 4.0, Internet of Things or IoT is not 4IR but only an enabler of it. Industry 4.0 is much more encompassing and covers amongst others the widespread incorporation of IoT, increased customisation, the full integration of advanced analytics and enhanced reliance on the cloud.

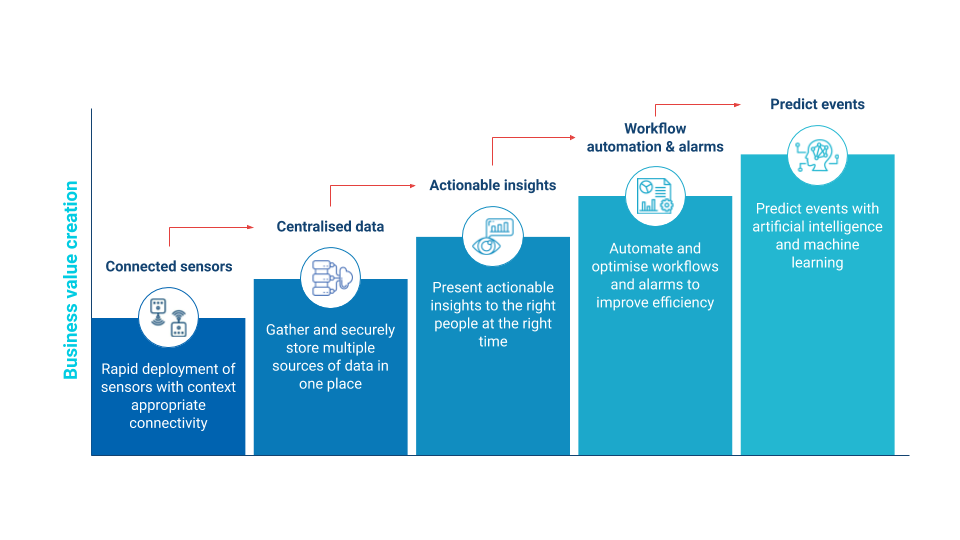

Transforming to Industry 4.0 is not rocket science and it does not require you to reinvent the wheel. Many businesses are moving to Industry 4.0 and are reaping the benefits such as a measurable impact on the bottom line. Fortunately, over the past decade, there have been advancements in the “move to Industry 4.0” process which made it possible for the complete business to transform without having to build everything from scratch. This means some of the existing systems and processes can be upgraded by adding and/or integrating the different layers of IoT without replacing everything. There are five layers of Industry 4.0 IoT; they are listed below.

3. The 5 layers of Industry 4.0

The above illustration shows the 5 different layers of IoT systems integration and how by implementing each of these layers, more value is unlocked.

Polymorph helps businesses transform to Industry 4.0 by implementing these 5 layers. Each layer will form the basis for the series of articles to follow in the next couple of weeks. Some organisations may have already implemented an aspect of these IoT components.

We have, therefore, conducted a free IoT maturity assessment which will give you an indication where and how you can improve your business and where Polymorph can help to transform your business.

4. What are the benefits of Industry 4.0?

Some of the benefits of Industry 4.0 include increased productivity and better management of resources, more effective decision-making based on real-time information and optimised and integrated production processes. It allows for flexibility as well as direct communication between clients and organisations which will see use better understanding customer needs. Furthermore, manufacturing time in both the design and merchandising of new products will reduce together with the percentage of defects and shrinkage.

Ultimately, it gives you a competitive advantage when considering that either your competition is going to make the transition and reap the benefits and you will be left behind. Or you can make the first move and secure the competitive advantage for your own business.